Box Styles

Here is a high level summary, with pictures of different box styles that you will see at Berkley!

These box styles apply to both paperboard and corrugated!

01

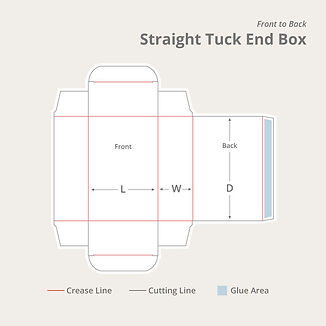

STRAIGHT TUCK-END CARTON (STE)

STE Cartons have the benefit of having

four clean folded edges on the face panel,

so that there are no raw edges.

The top and bottom lids both tuck to the

back, creating a clean brand presentation

for your product on the front of the box.

ADVANTAGES

-

Has four finished (uncut) edges on front for

-

better appearance than RTE’s

-

Can window to within 5/8” of front panel scores.

-

Glues same as RTE’s on straight-line gluer

-

Ships flat to customer.

02

REVERSE TUCK-END CARTON (RTE)

RTE Cartons cartons are generally more

economical than the STE, since it nests

well on the sheet.

This style features a top closure that tucks

from the rear to the front, while the

bottom closure tucks from the front to

the rear of the box.

ADVANTAGES

-

Economical

-

Nests on press for maximum use of stock

-

Glues fast on the straight-line gluer; ships flat to customer.

03

TUCK-TOP SNAP-LOCK BOTTOM CARTON

(TTSLB)

TTSLB Cartons cartons (also known

as 1-2-3 Bottom cartons) feature four

flaps that fold and lock to form the

bottom.

This style is more cost-effective than

the Tuck Top Auto Bottom but may

require more time to assemble.

ADVANTAGES

-

Stronger bottom than STE’s or RTE’s, using slightly less stock.

-

Bottom will usually sit flatter on shelf.

-

Same straight-line gluing speed as STE’s and RTE’s

-

Ships flat to customer.

04

TUCK-TOP AUTO BOTTOM CARTON

(TTAB)

TTAB Cartons cartons (also known as Hymes Lock

cartons) have the advantage of a stronger base

than a STE, RTE, or a snap-lock bottom since the

bottom panels are glued in place.

It also makes for faster assembly/fulfillments times.

ADVANTAGES

-

Stronger bottom than tucks or snap-locks

-

Sets up fast in manual loading

-

Ships flat to customer

05

FULL OVERLAP SEAL-END (FOSE)

FOSE Cartons cartons are generally

assembled, filled and sealed on

automatic packaging equipment lines.

If hand assembly and fulfillment is

being utilized, peel-off glue strips can

be applied for manual sealing.

ADVANTAGES

-

Ideal for Single-Use applications.

-

Same straight-line gluing speed as STE’s and RTE’s

-

Ships flat to customer.

06

ROLL-SIDE TRAY (RST)

RST’s don’t require gluing and can also be used as lid tops with

the use outer tape or shrink-wrapping to keep both ends sealed.

ADVANTAGES

-

Ideal for Single-Use applications.

-

No Gluing

-

Ships flat to customer

07

REGULAR SLOTTED CONTAINER (RSC)

An RSC is the most common type of box. This is synonymous with a box. Think - Amazon shipping boxes - those are RSCs

ADVANTAGES

-

No Cutting dies

-

Easy to assemble and tape

-

Economical

08

ROLL-END TUCK TOP (RETT)

RETT’s don’t require gluing and provide a sturdy all-in-one option. These are usually assembled by hand. This style of box is synonymous with your higher end e-commerce shipping box.

ADVANTAGES

-

No Gluing

-

Sturdy Construction

-

Ships flat to customer

09

Half Slotted Container (HSC)

This is the same as the Regular Slotted Container (RSC) except that one set of flaps is excluded. Often used as a lid for a tray or a display.

ADVANTAGES

-

Extremely fast to manufacture on high-speed machines.

-

This significantly reduces production costs and allows you to have product delivered in the fastest possible time frames.

-

works as a lid for PDQ and other style trays/boxes

-

Ships flat to customer.

10

PDQ Tray (pretty darn quick)

PDQ Trays are a very common merchandising vehicle in the packaging world. They can be produced in paperboard, corrugated and even metal, plastic and other permanent solutions. They often sit on a shelf, counter top of check out lane.

ADVANTAGES

-

Preloaded product for good display on shelf

-

No labor needed to merchandise at a store level - comes pre loaded

-

No Gluing

-

Sturdy Construction

-

Ships flat to customer